Hydraulic Equipment Repair

Here at HMS we have been performing complete hydraulic equipment repair since 1981. HMS repairs all cylinders, motors and valves. We also stock pumps, motors, valves, seal kits and accessories for all your hydraulic needs. In addition, HMS offers in house design.

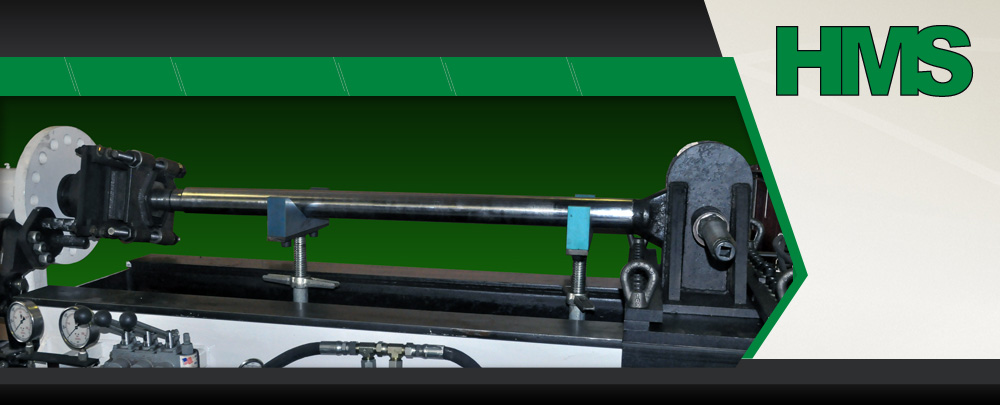

We have the facilities and equipment to disassemble, inspect, machine, chrome plate, reassemble and test your hydraulic equipment.

Servicing a wide cross section of hydraulic and pneumatic components for the refuse, heavy equipment, material handling and manufacturing industries, HMS carries a large inventory of replacement seals for hydraulic equipment. Our access to name brand after-market seals such as Parker, Hallite, Chesterton, Garlock and Poly Seal can save customers expensive downtime when seals are obsolete or unavailable from the O.E.M.

HMS also has access to generic seal kits for Caterpillar, Komatsu, Mitsubishi, John Deere, Case, and many other manufacturers.

In addition to seals, HMS also stocks pre-plated chrome rod in metric and inch sizes. Metric sizes are 22mm thru 110mm and inch sizes are 5/8” thru 4”.

Many sizes of CDS, DOM and HRS mechanical tubing, 6061 aluminum bar stock, 660 bronze and cast iron are stocked to machine replacement and obsolete parts.

PTFE, Phenolic and many other plastics are inventoried to help our customers when a custom application is required.

Hydraulic components require working parts that are flawless and free of defects. To assure maximum performance and customer satisfaction each cylinder, pump, motor and control valve is disassembled and inspected. After components are visually checked, micrometers and calipers are used to determine proper tolerance and abnormal wear. The results of the inspection are noted on our work order and are thoroughly reviewed with our customers.

With the customer's approval, HMS then completes the repairs needed using quality replacement parts and experienced personnel. The units are then tested, painted and stamped with a reference number.

HMS is committed to earning your respect, your confidence and your business. We take responsibility as your hydraulic component-reconditioning supplier. We strive to be your most valuable hydraulic resource.